Introduction to Silage Wrap

Imagine you’ve spent countless hours nurturing your crops, only to find them spoiled or wasted due to inadequate protection.

That’s where Silage Wrap steps in, a lifesaver for many farmers around the globe.

What is Silage Wrap?

Silage Wrap is also called bale wrap, or silage film by some ranchers. It is a stretch film primarily used to preserve silage, a fermented fodder utilized for feeding livestock.

Acting as an excellent cling barrier, it ensures that the stored forage retains its nutritional value. The high strength of bale wrap protects the forage from external elements like air, moisture, and pests.

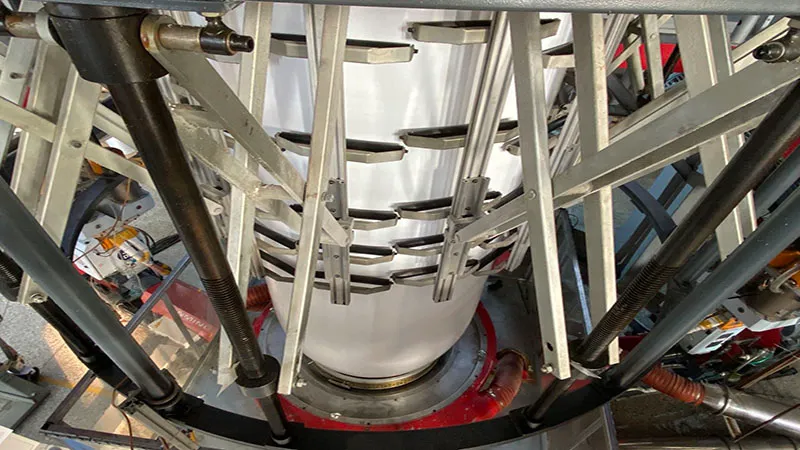

It is widely used for livestock feeding indoor storage, outdoor storage, and wrap bales. The bales can be Square or Round bales.

Choice & Price of Silage Wrap Roll

Mainstream brands: Sunfilm Silage Wrap, Bale Tuff, SilageGuru, 3X, etc.

Manufacturers: BPI, SilageGuru, Aspla, etc.

Standard Thickness: 1 mil, 1.2 mil 1.5 mil, etc.

Standard Size: 30 x 5000 ft

Why Bale Wrap is Crucial for Agricultural Success?

The fermentation process requires specific conditions to ensure optimal silage quality.

A well-sealed silage bale prevents the penetration of air, maintaining a controlled environment, and suitable heat buildup, which is vital for the fermentation process.

And guess what? Proper wrapping directly translates to healthier livestock and better dairy and meat products. Who wouldn’t want that?

Materials Used in Silage Wrap Rolls

Common Materials

The majority of Silage Bale Wrap is made from mLLDPE & LLDPE. Those materials are preferred due to their durability, stretchability, and strong resistance to UV rays.

Pros and Cons of Different Materials

While the high-density mLLDPE wraps offer excellent strength and stretchability, they might not be as resistant to punctures as some might desire.

On the flip side, high-density LLPDE tends to be more resistant to tears but might not provide the same level of strength.

So the decisions about Round Bales or Square Bales.

The Process of Using Silage Wrap

Step-by-Step Guide

- Prepare the silage by ensuring it has the right moisture content.

- Compact the silage to remove air pockets.

- Begin wrapping the bale, ensuring a minimum overlap of 50%.

- Use at least 6 layers of wrap for optimal protection.

- Store the wrapped bales in a location away from direct sunlight and potential pests.

Tips for Best Results

Always monitor the storage conditions, and make sure you’re using quality bale wrap equal to Sunfilm silage wrap.

And remember, it’s better to over-wrap than to skimp and risk the quality of your silage.

Longevity of Bale Wrap

Factors Influencing Longevity

Factors like the material of the stretch film, UV proportion, storage conditions, and even the application method play a role in determining the lifespan of your Silage Film Wrap.

How to Enhance Durability

Opt for wraps with enhanced UV protection and store them in shaded areas, especially in outdoor storage. Also, proper application—ensuring no tears or gaps—can significantly boost longevity.

Importance of Quality in Silage Wrap

Signs of Quality Wrap

A top-notch Silage Wrap roll will have a consistent thickness, high tear resistance, and optimal UV protection. It should also be easy to apply and stick to itself for a secure seal.

Impact of Poor-Quality Wraps

Skimping on quality might seem cost-effective in the short run, but think of the potential losses! Poor-quality wraps can lead to spoilage, resulting in financial losses and risks to livestock health.

Conclusion

In the vast world of silage, silage wrap rolls can make a big difference. Silage Wrap is one such “small” tool with massive implications for feed quality and livestock health.

By investing in the right wrap and using it correctly, you can ensure quality and longevity for your feed. After all, isn’t securing the fruits of your labor worth the extra effort?

Frequently Asked Questions (FAQs)

- What is the average lifespan of a good-quality Silage Wrap?

- Typically, a good quality wrap can last 12-24 months, depending on outdoor conditions and the material used.

- Can I reuse Silage Wrap?

- NO. To ensure the best protection for your silage, always use a fresh wrap.

- Is there an environmentally-friendly alternative to traditional Silage Wrap?

- Yes, some companies produce biodegradable or recyclable silage wraps.

- However, they might differ in terms of durability and cost compared to traditional wraps. It’s essential to search and choose based on your requirements and the product’s performance.

- What happens if the wrap is damaged after wrapping?

- If the Silage Wrap gets damaged, it can compromise the anaerobic conditions inside, possibly leading to spoilage or diminished feed quality.

- Does the color of the Silage Wrap matter?

- While the primary function of the wrap is to protect and stock the silage, the color can influence heat absorption, with darker colors generally absorbing more heat. Depending on your region’s climate, you might prefer one color over another.

- For instance, in cooler climates, black wrap might help in retaining heat, while in hotter areas, white or green wraps might be preferred to reflect sunlight and keep the bale cooler.